Introduction

The consortium of Boxco Logistics India Pvt Ltd and Deugro were awarded a contract to build a jetty for Units 3 and 4 of Kudankulam Nuclear Power Plant (KKNPP) for the Nuclear Power Corporation of India Limited. The project is in accordance with the intergovernmental agreement signed between the government of India and the Russian Federation. The equipment is coming from the Russian Federation and other countries by sea to Tuticorin Port (VOC Port). It is then transported using multimodal transport onto the Kudankulam project site. Boxco and Deugro together have so far handled over 60,000 FRT of cargo for this project. Over-dimensional and heavy lift cargo that cannot be transported by road will be loaded onto barges at Tuticorin Port and rolled out or unloaded at the new jetty near the plant site.

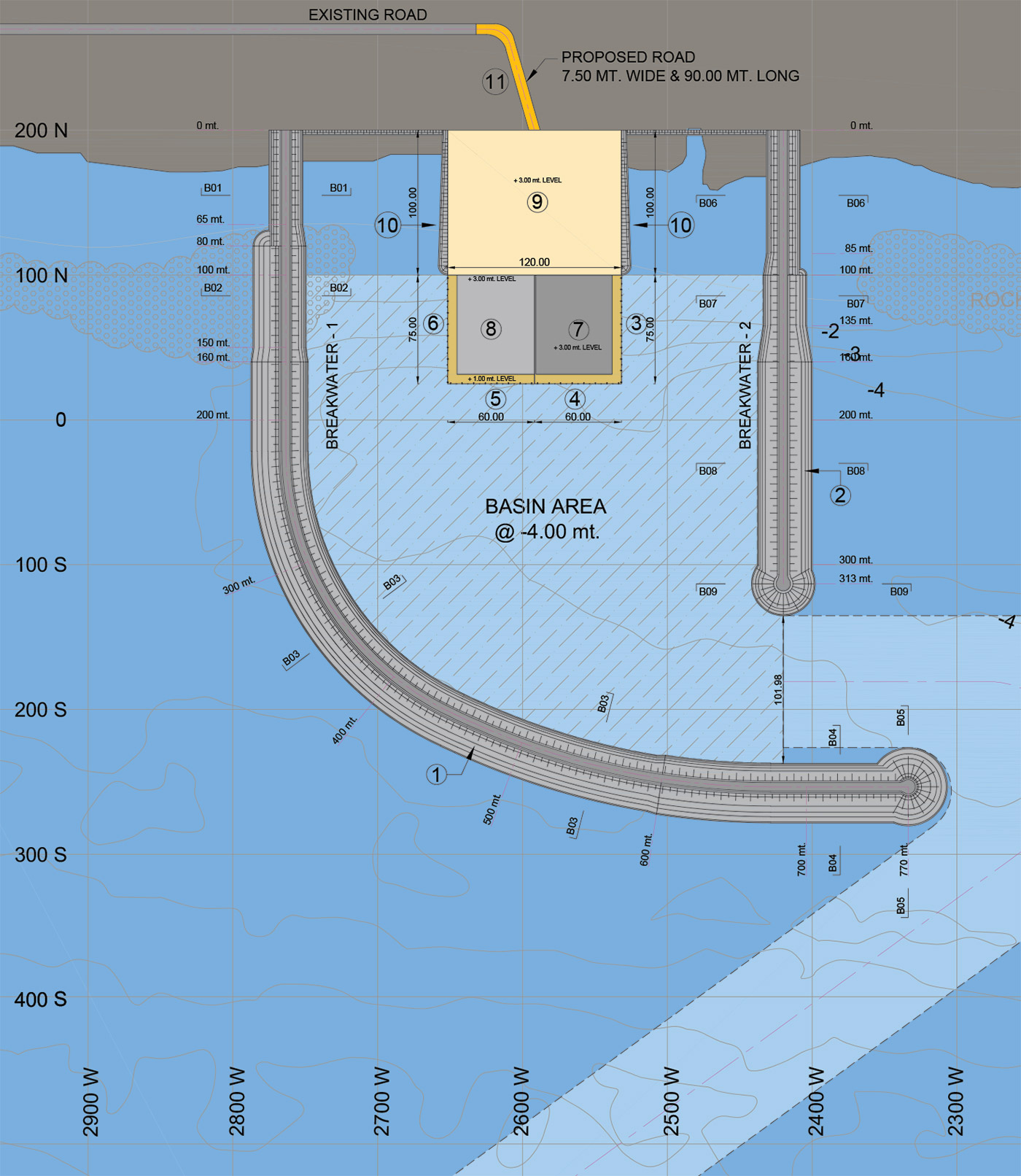

Our scope included gathering data to support the design, such as the sub-soil strata, oceanographic data (on waves, tides and currents) and bathymetric survey data. IIT Mumbai checked the design of the jetty and its associated structures, which included a mathematical modeling, and proof checking of the technical parameters.

- Construction was divided into four phases

- Breakwater, east arm

- Breakwater, west arm

- RoRo jetty operational area

- LoLo jetty operational area

Boxco designed and constructed the jetty, which is protected by a breakwater, and the associated facilities for the unloading of overdimensional cargo and heavy lift cargo from the coast near KKNPP for RoRo and LoLo operations. The jetty was constructed to withstand all weather conditions and its lifespan is 60 years. The design of the jetty and breakwater were approved by IIT Mumbai and certified by Bureau Veritas.

MAP OF THE BASIN SHOWING THE BREAKWATER

PHOTOGRAPH OF THE PORT SITE SO FAR

The protective breakwater is approximately 1,150 m long and extends into the open sea. It required 1.7 lakh of rocks of various sizes. The RoRo jetty is a gravity-type jetty with dimensions of 60 × 75 m. Its slope is 1 m, enabling easy negotiation of heavy haulage. The LoLo jetty is also a gravity-type jetty with dimensions of 60 × 75 m. The top of the jetty is flat with no slope.

Unique Challenges

The jetty is at the mouth of Gulf of Mannar and at the meeting point of three oceans. Constructing the breakwater was a complex task, as wind speeds can reach 45 km/hr. The swell rises from 0.75 m to 1.5 m on an average and on occasions it has touched 2.5 m. It was a challenging marine engineering job, extending 750 m out to the sea. Boxco is proud to have successfully completed both arms of the breakwater. During the last monsoon, the jetty was subjected to severe cyclones and it came out with flying colours as it was able to withstand all incursions by the cyclone. Dredging and blasting had to be carried out to produce an even draft of 4 m throughout the channel to allow navigation of vessels with a draft of up to 3 m.

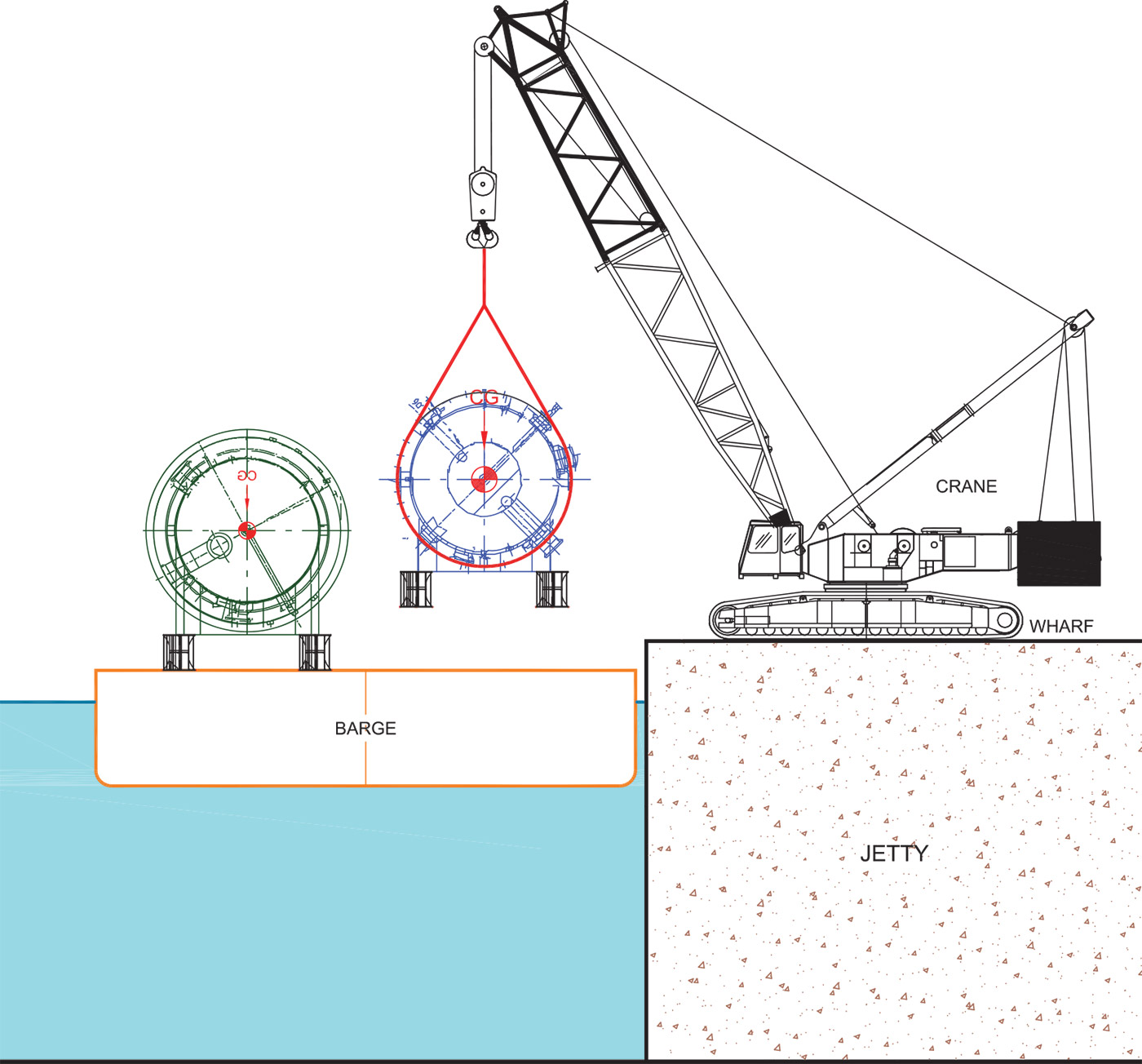

Barge Operations At KKNPP

Boxco has mobilised a 1100 ton capacity self-propelled barge named Akua Kuen from Kolkata for barge operations. The barge requires a depth of 4.0 m. It has a length of 57.19 m and a breadth of 16.40 m. It has an automatic self-ballasting and deballasting system to maintain its static position while conducting RoRo operations at the jetty. The barge is IRS certified.

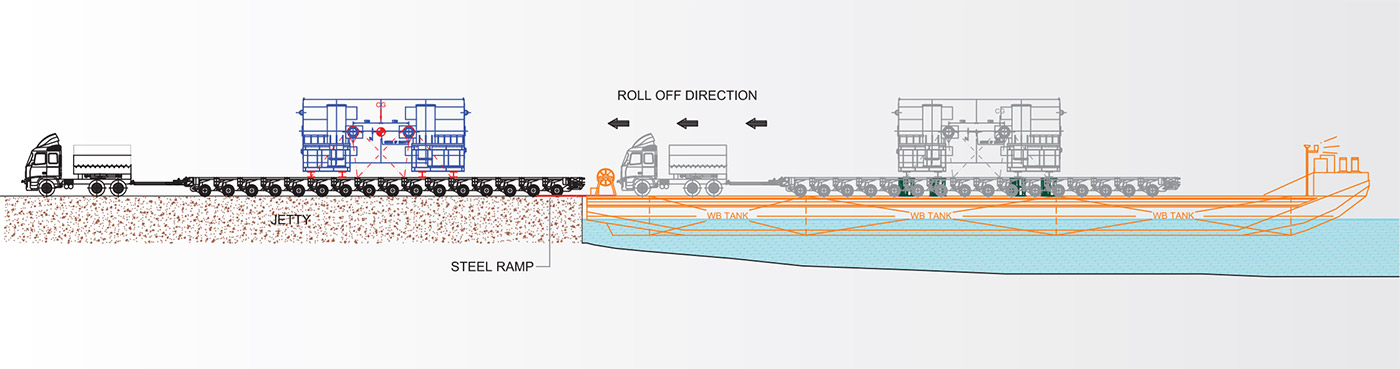

RoRo Operations

The first ro-ro operations at the jetty are planned for March 2019. In each voyage, approximately 600 tons of cargo will be shifted from Tuticorin Port to the KKNPP site. The project cargo will be rolled off from the barge using our axles.

SCHEMATIC VIEW OF A TYPICAL LoLo OPERATION. THE BARGE IS ALONGSIDE THE JETTY

SCHEMATIC VIEW OF A TYPICAL RoRo OPERATION. THE BARGE IS IN LINE WITH THE JETTY