The need for energy security and climate change mitigation have increased blending mandates (in fuels) worldwide. Growing concerns about the future of energy security and global warming have necessitated investments in biofuels—a key renewable energy source. The key drivers of this growth have been: (1) the rise in the number of countries worldwide enforcing blending mandates; (2) high oil prices and (3) incentives and assent to international protocols on global warming mitigation, and availability of climate finance for renewable energy development.

Zambia is poised to become a major contributor to the growth of the biofuels industry in Africa. It has abundant land that can be used for feedstock production, with a land–person ratio of 5.79 hectares (ha), which is relatively large when compared to the industrialized world at 0.01– 4.23 ha per capita. This is complemented by political stability and a climate that is conducive to a wide array of feedstocks that can be grown in tropical and subtropical regions. It’s near-central location within Southern Africa offers trade opportunities for feedstock and liquid biofuels. For bioethanol feedstocks, sugarcane, cassava, and maize are produced in large quantities.

Looking at the opportunities in the African nation, Arya Water Technologies (AWT) explored the possibility of venturing into water and wastewater treatment business in Zambia.

- AWT Bagged Two Orders Of

- Water treatment plant (WTP) and

- Wastewater treatment plant (WWTP) at Lusaka, capital of Zambia from M/S Surya Biofuel Ltd.

DISTILLERY BIODIGESTER

UF MEMBRANES SKID ASSEMBLY

AWT bagged the order by demonstrating complete understanding of client issues and proposed solutions with a combination of conventional and advanced technologies.

In the WTP project, AWT provided state of the art Ultra Filtration (UF) membranes, Reverse Osmosis (RO) membranes and Demineralization (DM) plant. The WTP shall produce a water of conductivity < 1µs/cm to be effectively used for ethanol dilution.

The WWTP is based on distillery biodigester process, wherein a Continuous Stirred tank reactor (CSTR) is provided. The system shall treat the critical spent wash generated from the molasses/grainbased feed distillation process. The spent wash is categorized as "difficult to treat" organic waste with a Chemical oxygen Demand (COD) value of 2.0-2.5 lakhs ppm.

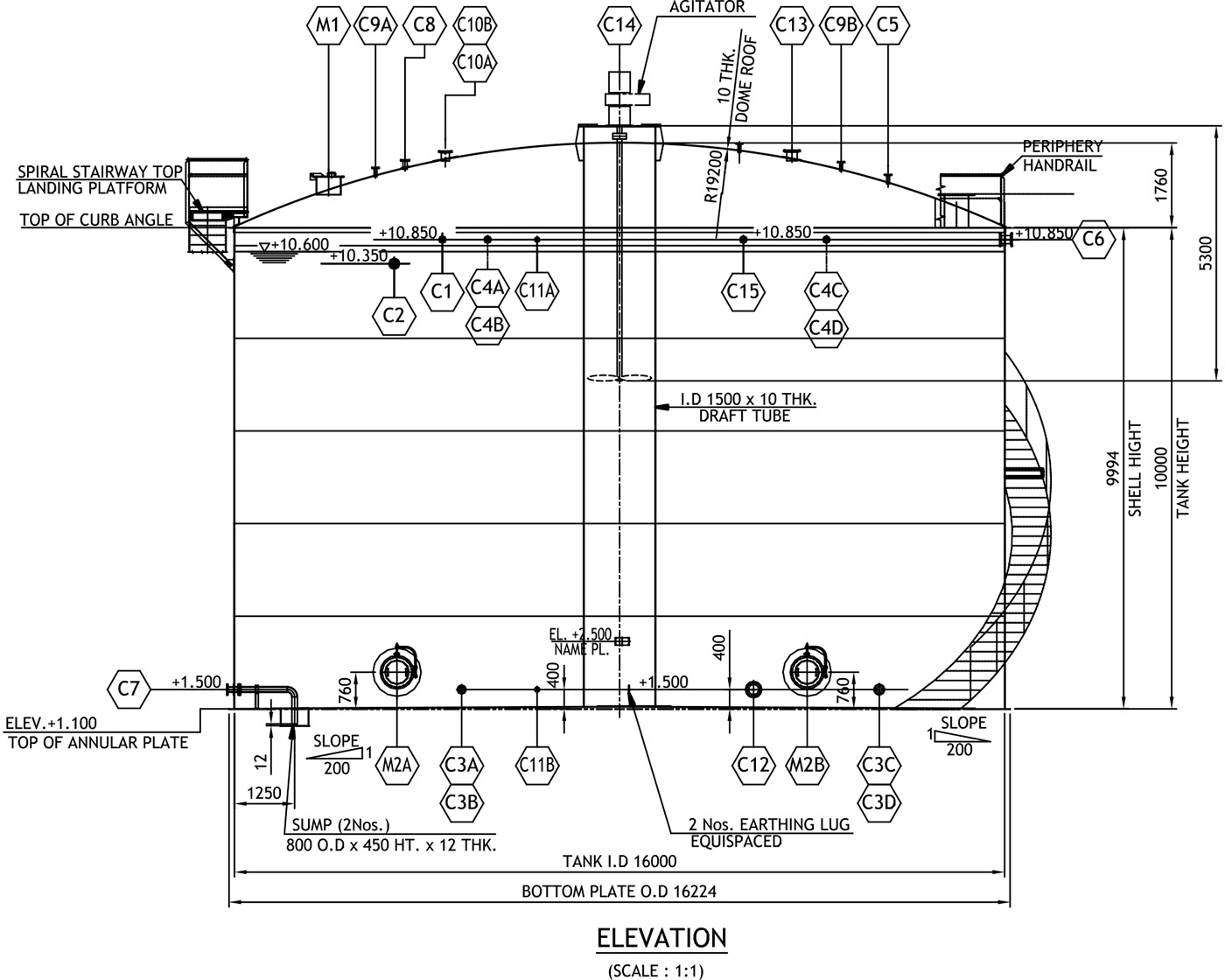

CSTR BASED DISTILLERY BIODIGESTER PLANT AND DESIGN DRAWING FOR ELEVATION

The waste water plant shall achieve 60-70 percent reduction in pollutant loads for further usage in bio feed/ sugarcane plantation.

Technology At A Glance

In a distillery, WTP is the backbone of distillery throughput, production volumes and revenues. By envisaging a UF -RO -DM based process, AWT have envisaged a best in class system.

In WWTP, pollutant loads were earlier removed by conventional processes such as bio composting which leads to higher footprints and lesser treatment efficiencies. By using Biodigester viz. CSTR, anaerobic degradation is enhanced which leads to better design and cost savings in downstream process.

- Key Features Of The Projects

- State-of-the-art treatment process

- Lesser footprint

- Treated water in WTP shall be conducive for ethanol/spirit dilution

- Enhanced organic degradation in Biodigester anaerobic treatment.

- Treated water and sludge from WWTP shall be used as natural fertilizer

UF -RO -DM PLANTS