It is said that its people are a company’s best assets. But what if the company also owns the best equipment? In some form or other, we are happy that Boxco is serving the logistics, heavy lift and compliance requirements of major projects.

Jawaharpur Vidyut Utpadan Nigam Ltd’s power project at Jawaharpur, a small town in the most populous state of India, Uttar Pradesh, was already being served by Boxco. Project import clearances and reconciliation sheets have been processed for several years. Quite unrelated to this service, Boxco also served the project through GE, by transporting the mega stators for the project.

A stator when seen does not look that intimidating in the world of heavy lifts. It is a mere 10.5 m in length by 4.26 m in width by 4.54 metres in height. However, the piece packs within its relatively small dimensions a whopping 358 MTs of carefully laminated and placed electrical steel sheets and windings, good enough to feed power to a small town. This weighty package needs a girder bridge to ensure its weight across its axles is spread onto the road to remain within acceptable limits. Moreover, it costs more than INR 600 million and takes about 12 to 15 months to build.

A monstrous yet delicate cargo at the same time!

It requires not only the best people but also the best equipment to move such beasts from their place of build to their operational site, where they will sit and work silently, chewing out electricity in large dollops, one turn of the rotor after another, for years and years, without respite.

A good portion of the plant is then built around the stator when it is placed.

All of the above mean that any delays in delivery were not an option. Any mishandling of the weighty dwarf could have resulted in either very expensive delays in this very expensive project or a less than optimum electricity generator, which would increase costs all round.

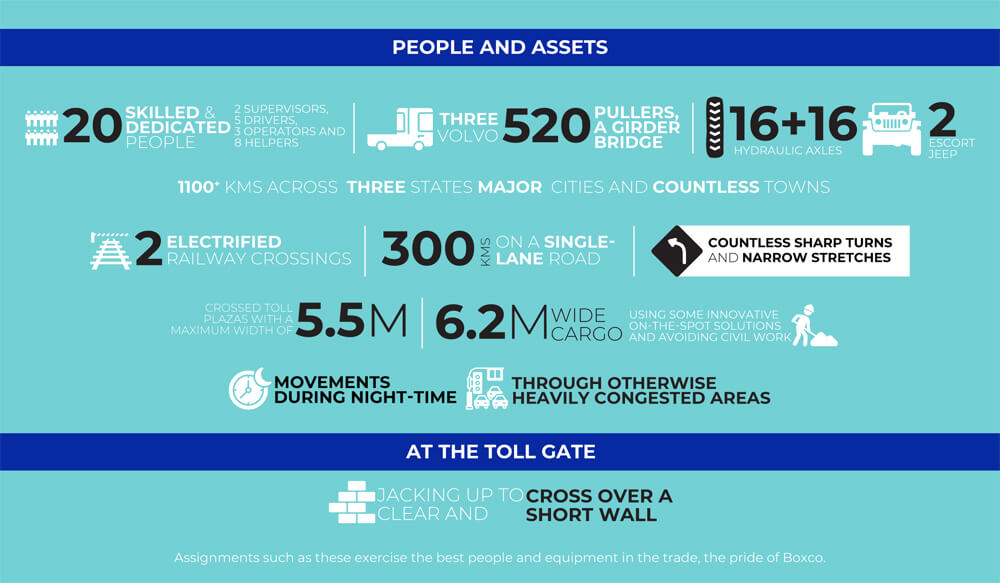

The transportation required careful planning of the route, which is approximately 1100 km long. In a country like India, 1100 km through various states means a riot of variety and vibrant scenes. However, different solutions need to be worked o ut for particular stretches, taking account of the strength of road surfaces, bridges, arches and other structures along the way.

The stator began its journey on 16½ axles. It covered vast stretches till near the site, safely ensconced in a cradle. Then 16 + 16 axles were required on a girder bridge and it safely ended its journey on the 16½-axle configuration. Covering the distance took a dedicated team of 20 personnel over 80 days.