Water resources are coming under immense pressure due to the allround economic growth, global warming, urbanization and incessantly rising water pollution levels globally. Lack of proper water treatment and management systems only accentuate the catastrophic effect on the entire civilization. The problem is expected to become even more severe in times to come.

Arya Water Technologies (AWT) is a leading provider of innovative solutions and technology used in industries such as chemical, electroplating, food and beverages, textiles, dairies, distilleries, breweries and others. We offer a complete basket of conventional and next generation technology-based offerings to address a spectrum of turnkey water treatment solutions across diverse segments. For the Dairy industry, AWT has the capabilities to execute operation by using a combination of equipment and speciality chemicals to meet the stringent norms. We provide wastewater treatment with advanced technologies. With our complete understanding of the nature of effluent, pollutant fingerprinting, knowledge on processing raw material and its characteristics; we are efficient in handling the worst effluent streams.

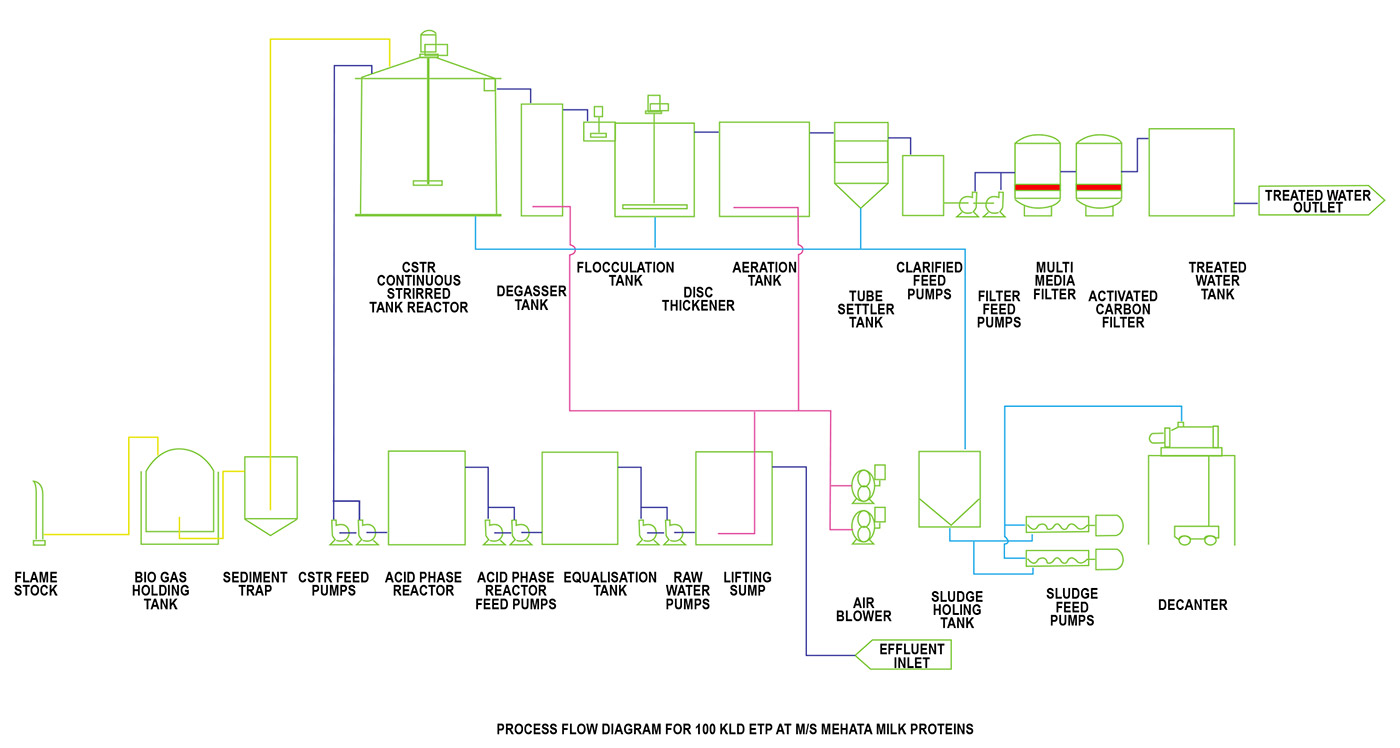

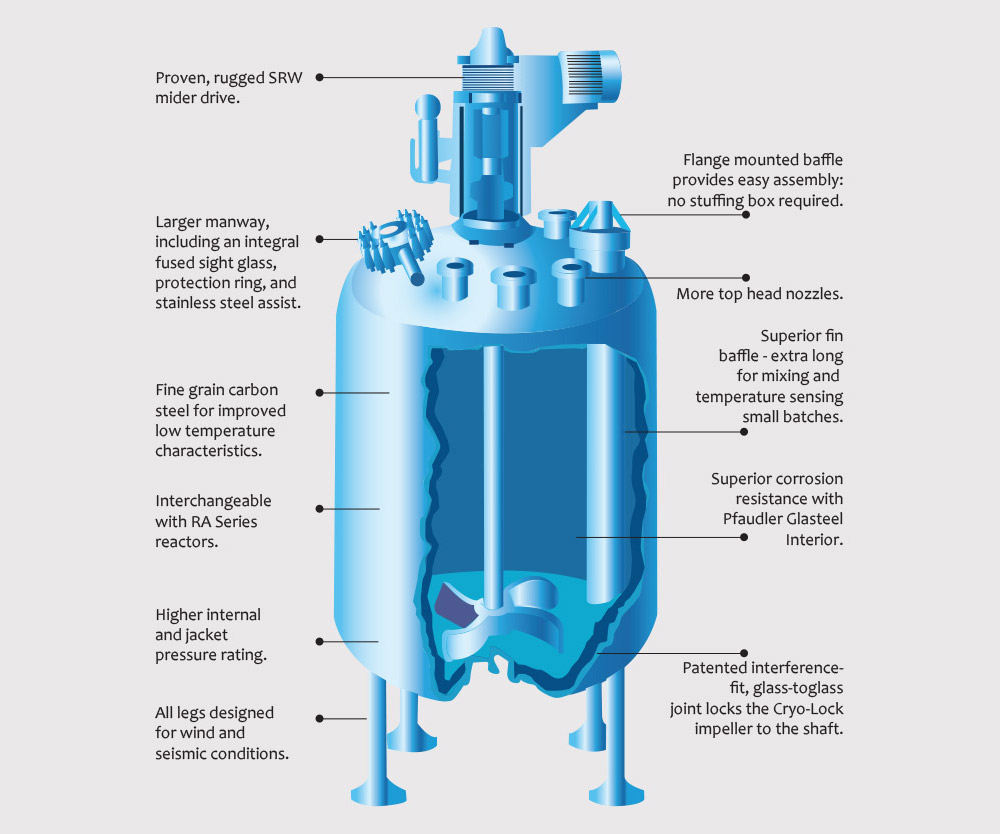

Fig 1 - Continuous Stirred Tank Reactor (CSTR)

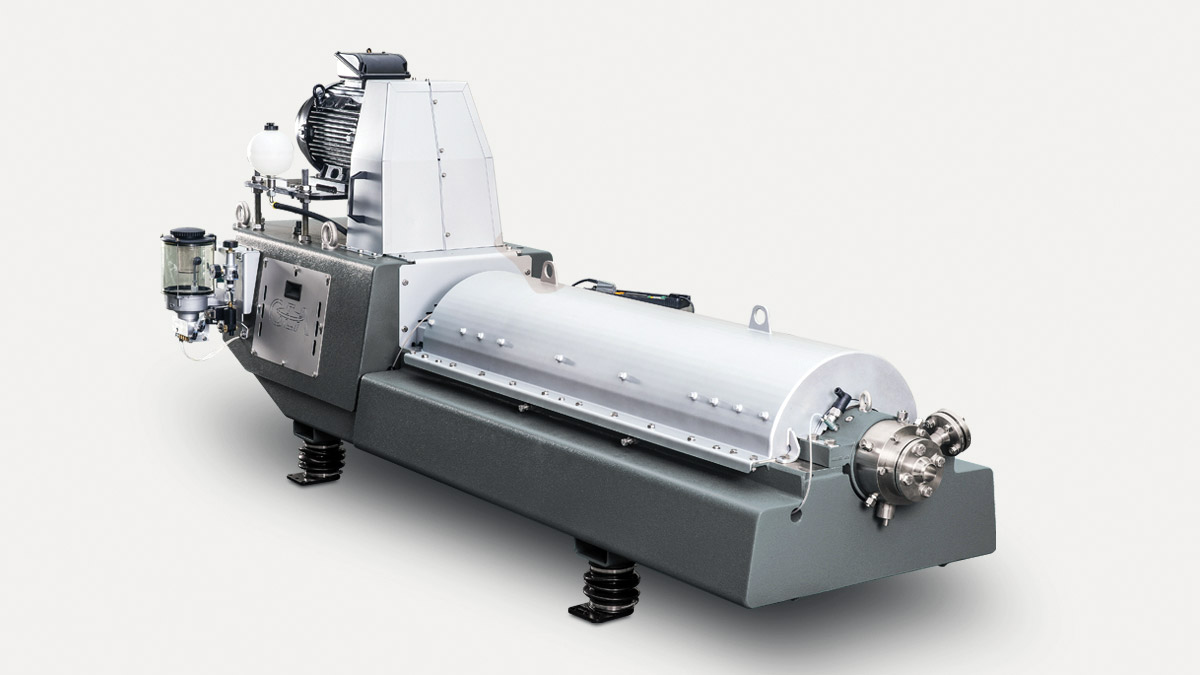

FIG 2 - DISC THICKNER

Typical Facts From Dairy Waste Water Treatment Case

AWT provides advanced process scheme comprising of anaerobic and aerobic reactors for efficient treatment of dairy and powder plant wastewater.

The process is designed to handle the complex loads being generated in the dairy and powder plant sector. These loads are highly organic and require high degree of treatment to impart sufficient oxygen levels to break the complex bonds. With inhouse design of anaerobic - aerobic treatment steps, the desired degree of treatment can be achieved.

- AWT bagged an order for 100 KLD ETP of Mehta Milk Proteins (MMP) at Kolhapur in December 2017. Mehta Milk Proteins is the new unit of Mehta Dairies better known as brand “Sphurti” in Dairy sector. The project consists of establishing the powder plant facility at Kolhapur; manufacturing process of which shall result in the generation of high organic wastewater. The treatment of such highly contaminated wastewater requires special treatment to meet the discharge norms as per the pollution control board.

FIG 3 - DECANTER CENTRIFUGE

AWT managed to bag the order with the technical pitch and advanced process scheme. In the project, we have given state-of-the-art wastewater treatment system. The process scheme consists of new age equipment such as Continuous stirred tank reactor (Fig -1) for anaerobic degradation, disc thickeners for sludge conditioning (Fig -2) and decanter centrifuge (Fig -3) for a clean solid liquid separation. Activated sludge process is used for aerobic treatment.

The plant shall achieve 95-98% reduction in pollutant loads and save the serene environment of the site from wastewater management hassles.

Advanced Technology At A Glance

In a typical wastewater treatment plant, pollutant loads are removed by conventional processes which leads to higher footprints and lesser treatment efficiencies. By using CSTR, anaerobic degradation is enhanced which leads to better design and cost savings in downstream aerobic process.

Disc thickener is helpful in biomass separation with added advantage of higher pollutant load removal. Decanter Centrifuge is a special solid liquid separation equipment which offers clean operation, better sludge recovery and consistency. Schematic is shown at the bottom of the page.

- Features of the project are listed as below

- State-of-the-art treatment process

- Lesser footprint

- Enhanced organic degradation in anaerobic treatment thereby saving on air requirement in aerobic treatment

- Best in class Sludge Management