With structural obstacles in the Unloading site and a road away from the foundation with restricting access, maneuvering ODC Cargo into their final assembly position was proving problematic for any crane or Engineering & transport company. In the face of such demanding site constraints, the company turned to a novel hydraulic skidding solution.

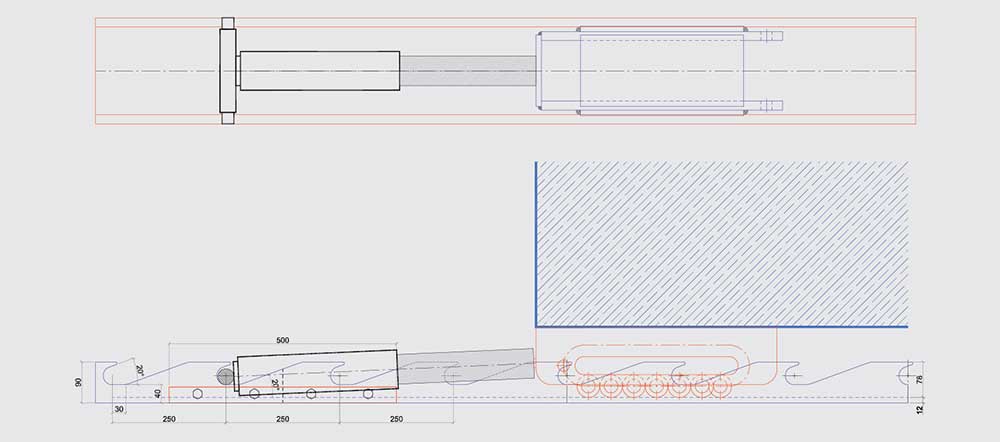

Boxco team calculated the component capacity required to skid 300 MT ODC and started preparing the initial designing on Autocad and arranging to dentify the material required by checking the material properties and specification.

We discussed with local cylinder manufacturer to build the push/ pull cylinder as per our requirement. Further, we identified the control valve from local market which was required to match with our specification. Most difficult part was to fabricate the track with sawtooth type cuts so cylinder can lock during push condition in that cuts and regain its position for next push by using the hydraulic lever without any manual help. A four roller shoes was developed in-house with each having capacity of 75 MT.

This is the perfect design for the Hydraulic skidding system due to its modular design, light weight and ease of assembly.

This system works on hydraulic and converts hydraulic pressure into mechanical movement.

- Following are the main benefits as compared to old Skidding method

- Rail track is not required Low operation time due to High Speed of Skidding.

- Skidding speed can be adjusted by cylinder control valve

- Skidding speed is 280mm / minute.

- Easy handling for operation.

- 50 % less operational time in comparison to conventional skidding system.

- Efficient and safe compared to traditional manual winch and pully system.

- Counterweight or anchor point not required.

- System will use weight of cargo as a counterweight.

- Easy to transport and cheaper compared to foreign skid system. Easy operation so any one can operate with a minimal training.

- Can skid up to 300 MT ODC Cargo and is the only hydraulic skid system available in India.

BOXCO displayed the system to our esteemed client “Wartsila Engines” who were convinced that this was the right equipment they were looking for all these years for skidding their engines. Wartsila immediately gave order to us for skidding of 7 nos. DG Set of 130 mtr at their site in Assam where they faced a lot of space constraints. Boxco successfully skidded the 7 numbers DG sets for a distance of 50 mtrs. After completing the job, Wartsila repeated the order to skid another engine of 130 MT at their site at Bawal, Haryana.

SKID SHOES WITH PUSH CYLINDER