Visakha Container Terminal (VCT), located on the centre of India’s east coast and closest to the Malacca Straits, is an ideal gateway for container traffic, with a unique hinterland covering a radius of 750 km from eight states – Andhra Pradesh, Telangana, Chhattisgarh, Odisha, Maharashtra, Jharkhand, Madhya Pradesh and West Bengal.

VCT is blessed with a natural depth of 16 meters alongside (deepest in the country) and state of the art container-handling infrastructure, including post Panamax STS cranes, latest NAVIS SPARCS N 4 software, more than 350 reefer plug points, adequate power back up, two full-length rail sidings, and it operates in a fully computerised environment. The Navis – N4 Terminal Operating System (TOS) has moved a step further and is completely integrated with the SAP system.

| Equipment | Current Count |

|---|---|

| RMQC | 6 |

| RTGC | 10 |

| Reach Stacker | 5 |

| Forklift | 3 |

| Tractor Trailer | 30 |

| Reefer Points | 350 |

| Berth Length | 450 m |

The terminal has two full-length on-dock rail sidings, which are operational 24/7. VCT had the privilege to handle rakes from Delhi, Nagpur in the past; however, the product did not continue for long due to implementation of the railways scheme route rationalisation, which has now been removed. The rail volumes at the terminal picked up the pace from the year 2014 with the conversion of Raipur-based cargo. The terminal has witnessed huge growth in rake handling, from four rakes a month to as high as 60 rakes a month now. Currently, VCT is providing services to major aluminium and steel players in Odisha. Furthermore, the terminal also handled Nepal-bound rakes during the years 2017–2019, following which CONCOR decided to move it from its MMLP. International Cargo Terminal (ICT), under the aegis of J M BA XI GROUP, deployed its own rakes on the east coast of India, connecting VCT to the hinterland in order to support the trade and cater for the prevailing demand. The terminal has well-established rail and road connectivity to the hinterland, thereby providing smooth access for cargo movement to the local hinterland and ICDs at NCR, Nagpur, Hyderabad, Raipur, and Kanpur besides Nepal. Also, VCT is accredited with ISO 9001:2015, ISO 14001:2015, OHSAS 18001: 2007, ISO 28000:2007, ISO / IEC 27001:2013 and has been conferred AEO status by Customs.

VCT is gradually evolving as a regional transshipment hub in the Bay of Bengal; containers from Kolkata, Haldia, Paradip, Kakinada, Chittagong and Yangon could get transhipped here. VCT operations started from June 2003 with only feeder vessels that plied between Vizag–Singapore and Colombo, while the local volumes at the terminal grew at a steady pace.

The transhipment volumes then commenced with the mainline services that started calling at the terminal, thereby providing the much-sought global connectivity from Visakhapatnam. VCT thus became the local transhipment hub primarily catering to Kolkata, which is a riverine port.

Keeping this growth in view, Visakhapatnam Port was identified in the National Maritime Agenda 2010:2020 to be developed as a transhipment hub. VCT witnessed a surge in transhipment volumes up to 2014; it slowed down before again picking up during the FY 2019 and 2020. However, the full potential of transhipment volumes is yet to be realised. There is huge opportunity for Visakhapatnam to become the regional transhipment hub. With the continuous growth in transhipment volumes and with patronage from various lines, feeder operators and NVOCCs, the growth rate is expected to rise further.

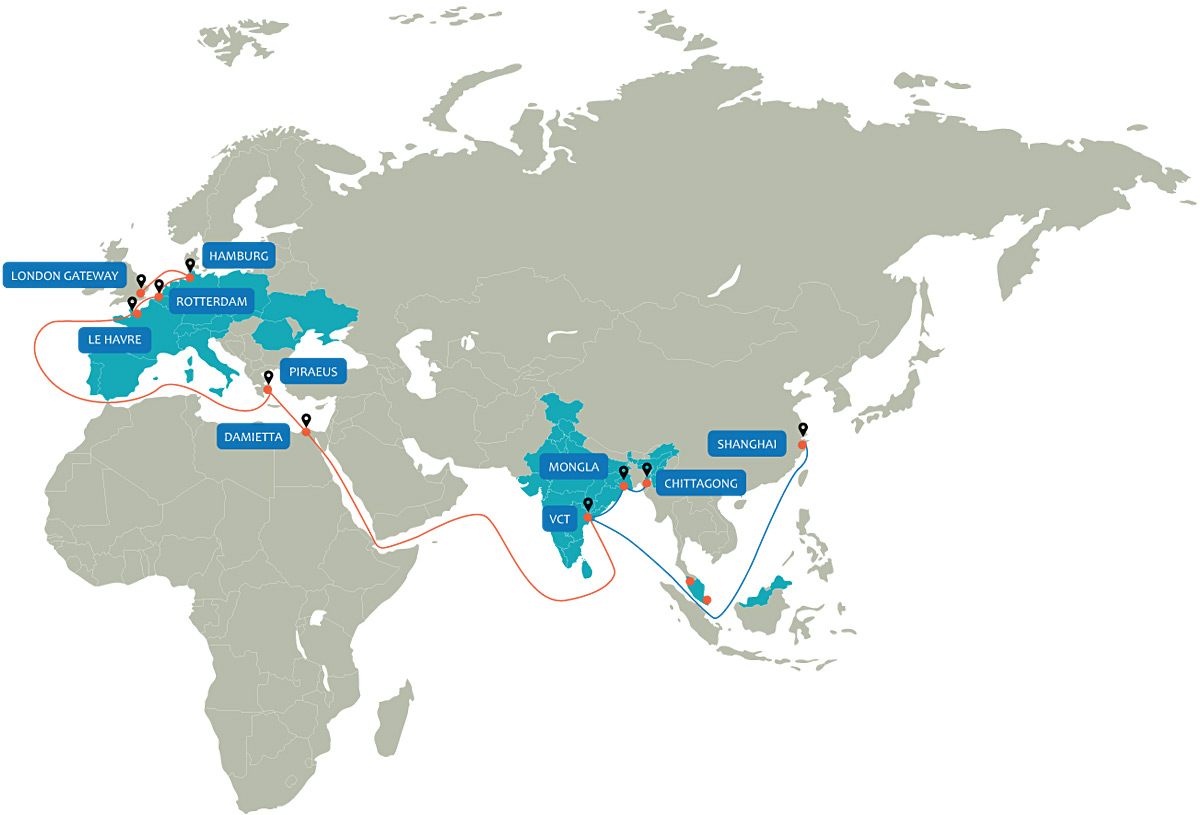

In terms of service profile and sectoral coverage VCT has three mainline services, namely FME, CHX and MDM services towards the eastern sea lane, which feature major mainline operators such as Maersk, Cosco, CMA-APL, Wan Hai, RCL, KMTC, TSL and feeder service providers such as Feedertech and BTL that cater to volumes towards South East Asia and the Far East. To the Arabian Gulf, Evergreen and Global Feeders operate the CCG service, while the CVK service of MSC connects VCT to Colombo. The IEX service connects the terminal to the Mediterranean and Europe region directly, with the participation of major lines like Hapag Lloyd, Cosco, OOCL, YML and ONE. In terms of connectivity for Indian coastal services, Shreyas and Sima Marine link VCT to Kolkata and Haldia, along with the Cochin and Kandla regions. The latest development is the direct service to the Mediterranean and Europe, which will also bring connectivity with Africa and the Americas from VCT, thereby making VCT a terminal with truly global coverage.

With best proximity to the feeder ports expanding up to Chittagong and Yangon complemented by a well-established feeder network (work in progress) VCT is excitingly poised to become the preferred regional transhipment hub on the east coast of India. The commercial benefits (discounts on vessel-related charges) offered by Visakhapatnam Port Trust makes the product even more attractive, sustainable and competitive in the long run, by being the ‘Gateway to the East’ blessed with burgeoning local hinterland and ever-increasing rail traffic.

Besides the commercial advantage offered by VCT for transhipment, the operational parameters justifying the transhipment are depicted in the tables below.

| Sea Distances From / To Kolkata | ||

|---|---|---|

| Ports | Nautical Miles | Transit Time (in days) |

| Vizag | 436 | 1.3 |

| Krishnapatnam | 707 | 2.1 |

| Chennai | 750 | 2.2 |

| Distance (In Nautical Miles) | ||||

|---|---|---|---|---|

| Ports | VCT | KPCT | Chennai | JNPT |

| Chittagong | 578 | 929 | 891 | 2160 |

| Mongla | 480 | 954 | 1022 | 2228 |

| Pangaon | 735 | 1048 | 1204 | 2317 |

Eighteen years of excellence have passed for VCT since its inception, with many challenges and successes. Understanding the COVID-19 situation , the global pandemic, VCT immediately leapt into action to ensure customers’ requirements were met, with communication continuing through phones, mails, messages, WhatsApp etc. Moreover, meetings with the trade were conducted through virtual platforms. Likewise, terminal staff were also asked to work in rotational shifts to eliminate man–man interface, while many others worked from home. VCT was also available 24/7 for customers to give them the best service in an uninterrupted manner. Furthermore, constant communication with local, port and other government authorities continued to broadcast information on the latest advisories.

- A few of the initiatives taken at the terminal during the pandemic were as follows:

- Posters / signage placed in the terminal to spread awareness.

- Innovation – in-house hands-free sanitisers produced.

- Innovation – steam facility made in-house for sanitising personnel in the terminal.

- The support of IT platform was taken exclusively to eliminate delays in service.

- Online visitor management system – visits only on approval basis.

While the terminal ensured the safety and health of the staff consistently by following global guidelines, operations performance was handled equally efficiently.

The year 2020–2021 has been remarkable for VCT in many respects. This has included the highest monthly throughput ever achieved – over 46,000 TEUs twice in the months of June and September. There was yet another instance, the highest reefer volume handled – over 3,400 TEUs in June. Not to forget the rail-bound traffic – as much as 60 rakes were handled and volumes crossed the 9,100 TEUs mark. This was all thanks to the trade, which has been supportive as always, and our valued patrons’ support. A few feathers have been added to the VCT cap, where MSC introduced its own tonnage in the month of July that plies between Visakhapatnam and Colombo connecting the Mediterranean, Europe, US and Africa.

Similarly, ICT under the aegis of J M BA XI GROUP has deployed its own rakes on the east coast of India, connecting the terminal and its hinterland, especially for Jindal Stainless Limited in Jajpur, Odisha. The maiden ICT rake moved from VCT on 24 July 2020.

The operational performance has been consistent at the terminal, with improved vessel turnaround time – an average of 21 hours per vessel. The truck turnaround time has dropped below 40 minutes, thus showing greater efficiency in performance. Ship and crane productivity has also showcased growth – 10% and 5% respectively. The highest parcel size was handled on Vessel Mexico, CHX service, with an exchange of 3,770 TEUs. Interestingly, a new productivity record was established on the same vessel, with 110 moves per hour completing a total of 2,113 moves in just 19.4 hours.

The laden volumes have also increased; thus parcel size is moving up. However, there have been ups and downs in the volume. While exports have shown a positive trend, imports are yet to return to normalcy. The demand for cargo continues to be on the higher side and the requirement for container equipment is equally high too. With the induction of additional quay cranes, terminal productivity has been enhanced considerably, reducing the berth stay of the container vessels calling at VCT. This has enabled considerable savings to vessel operators, with faster turnaround of their vessels calling at VCT.

VCT has been recording year-on-year growth, with a CAGR of 22% since inception. Plans have been drawn up for further expansion as well, and the work is in full swing. The terminal will have a longer quay line (~ 850 m) for berthing container vessels and 1.3 million TEUs in capacity very soon. Given the natural advantages that this port enjoys owing to its location, access, natural assets, connectivity, and the burgeoning industry that surrounds it, VCT is expected to continue to grow at the pace that has been established over the last few years – possibly at an even higher rate.

To handle the envisaged container traffic, VCT is moving at a fast pace speed to complete the expansion of the terminal. Post-expansion, the 0.6 million TEUs capacity terminal will be enhanced to 1.3 million TEUs capacity, when the next generation of ships, with 12,000–14000 TEUs capacity to handle the largest container vessel. The separate approach road to the terminal is ready.

200 m of the 395 m quay wall is getting ready for operations shortly allowing for two vessels to be handled at the same time.

Orders have been placed for three new super post Panama quay cranes and nine e-RTGCs, which are expected to be delivered by September 2021.

| Equipment | Current | Upcoming |

|---|---|---|

| RMQC | 6 | 3 |

| RTGC | 10 | 9 |

| Reach Stacker | 5 | 5 |

| Tractor Trailers | 30 | 24 |

| Reefer | 360 | 240 |

| Berth Length | 450 M | 395 M |

| Depth | 16 M | |

- Yard Reclamation Work In Progress